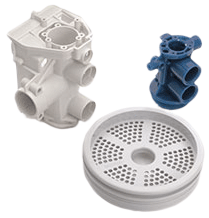

Injection molding

MCA's unique injection molding expertise includes...

25 machines ranging from 40 to 880 ton—to guarantee our customers the shortest lead times on all jobs large and small. Our expertise and support equipment for handling and processing high-temperature engineering plastics enable us to deliver the critical geometries and superior cosmetics demanded of these high-performance materials.

What's more, MCA performs insert molding using plastic-on-plastic, and plastic-on-metal combinations with our shuttle, rotary, and conventional molding machines.

Further, MCA's small high-speed, fully-automatic machines produce tight tolerances, offering both manufacturing precision and economy.

When you need special operations or extra support, MCA has it. Our auxiliary equipment and operations include gas-assisted molding, annealing, moisture conditioning, and more.

We manage your project from pre-production engineering, through moldmaking, production startup, secondary operations, assembly and packaging of finished parts—to your complete satisfaction.